BGA Rework & Reballing

Macrotron is a recognized provider of top-quality Ball Grid Array assembly and component services of all kinds. Our equipment includes top-of-the line BGA rework systems and an experienced staff of technicians with in-depth knowledge of BGA technology.

Our range of services includes:

» The removal, replacement, and salvaging of components» X-ray inspection

» Circuit pattern design changes at BGA sites

» Repair of lifted or missing BGA pads

» Repair of solder mask at the BGA sites

Our top-quality services are suitable for fast and cost effective quality BGA rework & reballing.

BGA Pad and Solder Mask Repair

Repair of damaged solder mask between BGA pads and connecting vias is a critical step to prevent solder from flowing down the vias during BGA replacement.

Damaged or missing BGA pads are replaced by following an IPC recommended procedure BGA Pad Repair Procedure. This procedure uses specially fabricated adhesive backed BGA pads that are thermally bonded to the board surface.

BGA Site Modification

When your design requires a change or modification at a BGA site, using a standard jumper wire is normally not an option. Jumper wires are simply to large to fit under a BGA component. This ingenious modification procedure uses flat copper ribbon thin enough to fit safely under the BGA component.

BGA Component Removal and Replacement

This combination provides you with a repeatable process with every project meeting the highest quality standards.

We're recognized as an industry leader in BGA services and have been qualified by companies around the world. Whether you have one board or one thousand boards for rework, we're the company to turn to for BGA rework services.

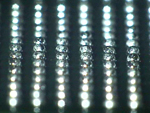

X-ray Inspection

X-ray services for BGA component and site inspection is completed on every board we process to ensure the highest quality level. This system will pin point defects including solder joint shorts, opens, and voids. This X-ray image reveals a range of solder joint defects.